While the first two editions of How To Make It In America (links below) focused on raw fabric importation and developing domestic supply chain partnerships, Recreator’s mission to achieve locally produced, sustainable and community-engaging enterprise has never seemed more urgent – we are more than excited to share the next steps of our journey into the regenerative fashion movement.

The Recreator brand originated with a faithful leap of a few guys from the Midwest into living and working full time from the heart of the Los Angeles Arts & Fashion Districts. We felt hemp was the holy grail of fiber in terms of sustainability and technical performance, and thanks to the support of our Kickstarter backers, we were able to source the most sustainable, high-performing natural textiles possible.

Along the way, our founders learned from researchers and fashion designers about the potential for bast fibers like hemp and how to best incorporate them into modern and high-comfort clothing collections. Beneath the product lines, we were just as hopeful in our pursuits to re-contextualize hemp – and cannabis – as a primary natural resource to address issues like climate change, sustainable manufacturing, soil regeneration, social justice, as well as health and wellness through cannabinoid compounds such as those possible in CBD oils.

+ Recreator team member inspecting a hemp fiber variety in Southern Colorado.

+ Recreator team member inspecting a hemp fiber variety in Southern Colorado.

In LA, we initially ran a digital garment print shop as we networked and traded services to learn the local fashion skill set: design, material sourcing, dyeing, cutting, sewing and finishing. Through our travels and time in production, we worked with some of the country’s most experienced textile designers and garment makers, always reflecting on each phase of our production process as we assessed the environmental costs of hyper-growth models behind all Fast Fashion trends.

FAST FASHION & FREE TRADE-OFFS

Why is Fast Fashion a problem you ask? Here's the short and quick of it from the experts at Fibershed, "... all the phases responsible for getting us dressed each day — creates more CO2 emissions than international flights and maritime shipping, combined. The pace of production and consumption has accelerated so quickly that one garbage truck of textiles goes to the landfill or incinerator every second. We call this fast fashion, and it has created a culture of clothing that is practically single-use."

Because of the sad state of affairs that U.S. textile manufacturing finds itself in after decades of offshoring domestic manufacturing to make cheaper goods, as well as the long-running drug war that restricted industrial hemp seeds in American soils, Recreator has been forced since its inception to import raw knit fabrics from China. While we trusted the safety and quality of our products, there was still too much we didn't know about our supply chain's true carbon or pollution costs ... We had to unravel the problem.

+ An exclusive Recreator (REC) raw hemp fiber produced into yarn grown, processed and manufactured 100% in the USA.

+ An exclusive Recreator (REC) raw hemp fiber produced into yarn grown, processed and manufactured 100% in the USA.

To solve this logistics riddle and to better live our values, new brand leadership decided to temporarily halt all new Recreator productions until a progressive standard in sustainability could be met. From the bags and tags that go into shipping our goods, to the size and speed of a responsibly-grown supply chain, to escalating environmental concerns and workers' rights, we now have a chance to make our new normal and a new future for "slow fashion" and textiles in America.

Based in our respect and budding partnerships with U.S. farmers and factories, in early 2018 our team began researching and modeling textile design inside a regional supply network. We see this as a way to begin reconnecting clothing to culture and place, which means it's connecting people and communities with every sale. That's something we can be proud of.

While the fibers of cannabis hemp are the unbreakable thread tying all things together in our products and stories, materials such as flax, nettle, wool, milkweed, cashmere and cotton have also become allies in our journey deeper into the world of sustainable natural fibers.

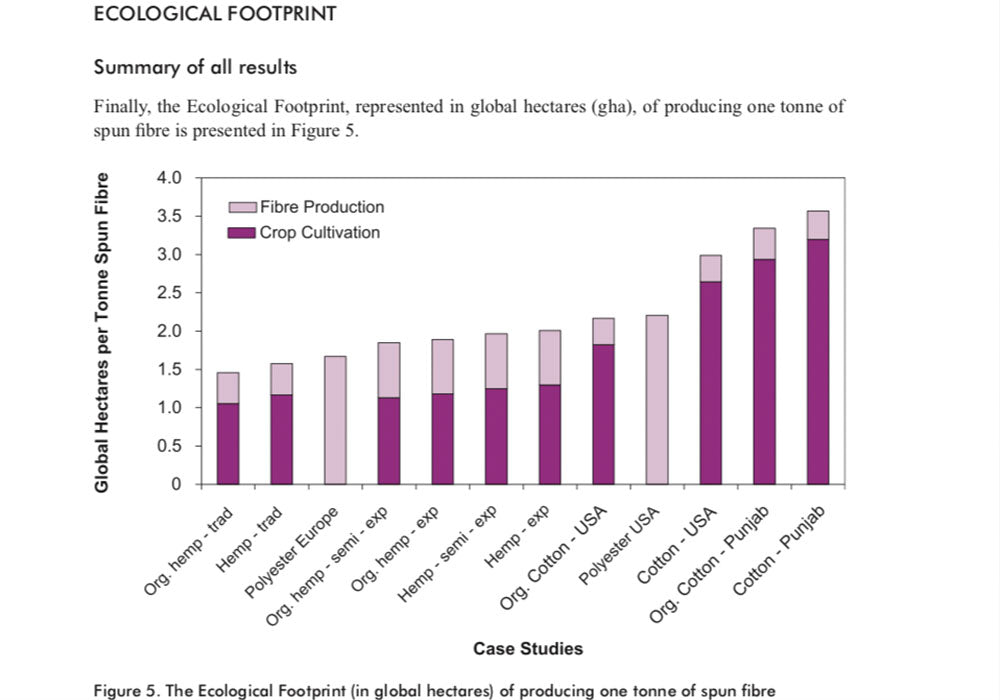

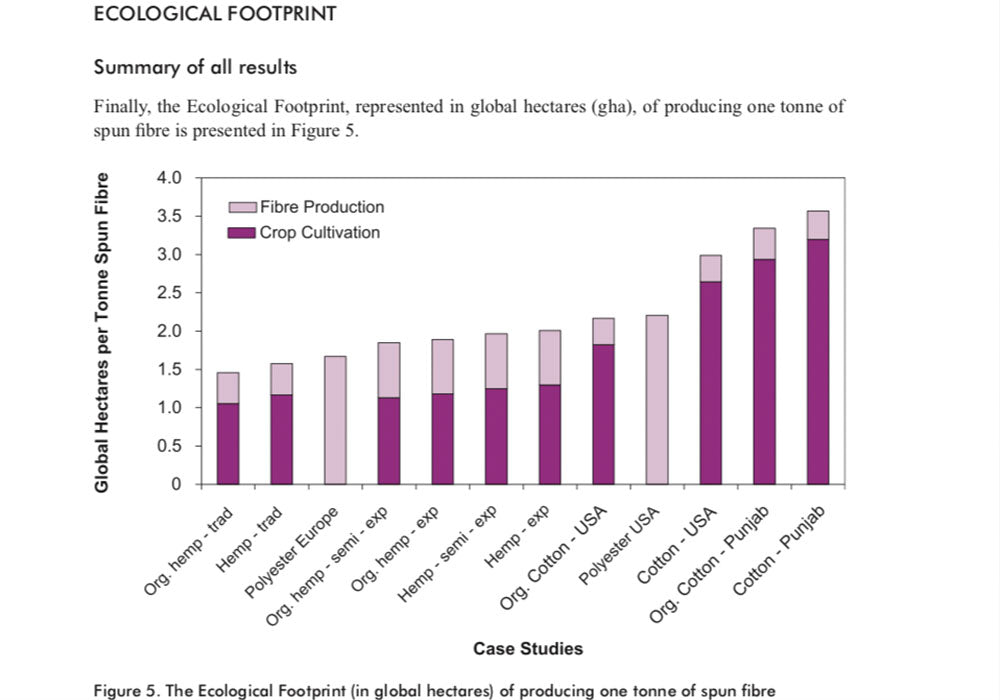

+ Research from a 2005 study by the Stockholm Environment Institute

+ Research from a 2005 study by the Stockholm Environment Institute

BRING IT HOME –> 2018 Farm Bill & Hemp Textiles

The nature of textiles in America is set to shift in so many ways as new digital technologies come online, and with favorable happenings at the federal level, full investment in the hemp industry can finally commence. In 2018, the Farm Bill “re-legalized” the golden hemp fiber as a commodity, providing us a first run at domestically sourcing our base materials in hopes of achieving R&D milestones.

Between the initial seeds sown in the Midwest to the final stitch in Los Angeles, we’ve realized that a product from our brand has to be more than just selling greater and greater quantities of garments to hit next season's sales cycles – our products have to tell a story of appreciation, innovation and creativity, of supreme quality and originality as inspired by the lessons of Nature.

With a clearer-eyed understanding of recreating fashion from fast, to full circle, from soil to stitch to soil again, our first trial to commercial hemp yarn production on and from US soil in over 70 years is complete and ready for the next phase: How to make it better in America.

UP NEXT >>> In Part IV of this series, expect images and information on the Recreator process for making yarns and textiles from American-grown hemp fiber.

- - - - - - -

+ Read Part I or Part II in our series about building American grown & sewn yarns, textiles, & sustainable finished fiber goods – How To Make It In America

+ Recreator team member inspecting a hemp fiber variety in Southern Colorado.

+ Recreator team member inspecting a hemp fiber variety in Southern Colorado.  + An exclusive Recreator (REC) raw hemp fiber produced into yarn grown, processed and manufactured 100% in the USA.

+ An exclusive Recreator (REC) raw hemp fiber produced into yarn grown, processed and manufactured 100% in the USA. + Research from a 2005 study by the

+ Research from a 2005 study by the